1. Understanding the degradation of structural materials by in-situ TEM study.

The degradation of structural materials under harsh environments, such as high temperature, corrosion, radiation damage and mechanical deformation, may lead to a series of problems impacting the society and economy. For example, rust induced by corrosion is one of the main causes of bridge accidents. For another example, the hydrogen generated by the water-side high-temperature oxidation of zirconium alloy led to the explosions in the Fukushima accident.

Understanding the fundamental mechanisms of materials’s degradation is vital for the development of more robust structural materials. The micro-structures and defects in materials have a great impact on the performance of materials, while they are usually too small to be characterized by human’s eyes and optical microscopes. In-situ transmission electron microscopy (TEM) technique enables the direct observation of the evolution of microstructures and defects at a spatial resolution scaling from 0.1 nm to 10,000 nm, offering the opportunity to discover or validate the fundamental mechanisms of materials’ failure at the atomic or nano scale.

Publications:

[6] Evaluating the effects of pillar shape and gallium ion beam damage on the mechanical properties of single crystal aluminum nanopillars, Yang Yang†, Sarah Y. Wang†, Bin Xiang, Sheng Yin, Thomas C. Pekin, Xiaoqing Li, Ruopeng Zhang, Kayla Yano, David Hwang, Mark Asta, Costas Grigoropoulos, Frances I. Allen, and Andrew M. Minor, Journal of Materials Research, (2021).

[5] Achieving large uniform tensile elasticity in microfabricated diamond, Chaoqun Dang†, Jyh-Pin Chou†, Bing Dai†, Chang-Ti Chou†, Yang Yang, Rong Fan, Weitong Lin, Fanling Meng, Alice Hu, Jiaqi Zhu, Jiecai Han, Andrew M. Minor, Ju Li, Yang Lu, Science 371, 76–78 (2021)

[4] Carbon nanotube (CNT) metal composites exhibit greatly reduced radiation damage, Kang Pyo So†, Penghui Cao†, Yang Yang, Jong Gil Park, Mingda Li, Long Yan, Jing Hu, Mark Kirk, Meimei Li, Young Hee Lee, Michael P.Short, Ju Li, Acta Materialia, 2020

[3] Atomic-scale phase separation induced clustering of solute atoms, Lianfeng Zou†, Penghui Cao†, Yinkai Lei†, Dmitri Zakharov, Xianhu Sun, Stephen D. House, Langli Luo, Jonathan Li, Yang Yang, Qiyue Yin, Xiaobo Chen, Chaoran Li, Hailang Qin, Eric A. Stach, Judith C. Yang, Guofeng Wang & Guangwen Zhou, Nat Commun 11, 3934 (2020)

[2] Liquid-Like, Self-Healing Aluminum Oxide during Deformation at Room Temperature, Yang Yang, Akihiro Kushima, Weizhong Han, Huolin Xin and Ju Li, Nano Letters 18 (2018) 2492-2497.

[1] Bimetallic nanoparticle oxidation in three dimensions by chemically sensitive electron tomography and in situ transmission electron microscopy, Weiwei Xia, Yang Yang, Qingping Meng, Zhiping Deng, Mingxing Gong, Jie Wang, Deli Wang, Yimei Zhu, Litao Sun, Feng Xu, Ju Li and Huolin Xin, ACS Nano, (2018) 12, 7866-7874.

2. IM3D: an open-source, MPI-parallelized and full-3D Monte Carlo simulation code for ion radiation in matter

Nanoscale ion implantation represents an expanding, interdisciplinary field that combines radiation effects with nanoengineering to control matter at the atomic level. In so doing it offers the potential to create novel nano-devices such as quantum computers, magnetometers, nanowire p–n junctions etc. In particular, ion implantation enables more precise control of the spatial distribution and concentration of dopants/vacancies, making it highly desirable for the reproducible fabrication of nano-devices. However, confidently taking advantage of it hinges upon the accurate knowledge of the spatial distribution of point defects (including dopants, vacancies, and self-interstitials) created by ion implantation, which is often predicted by Monte Carlo (MC) simulations.

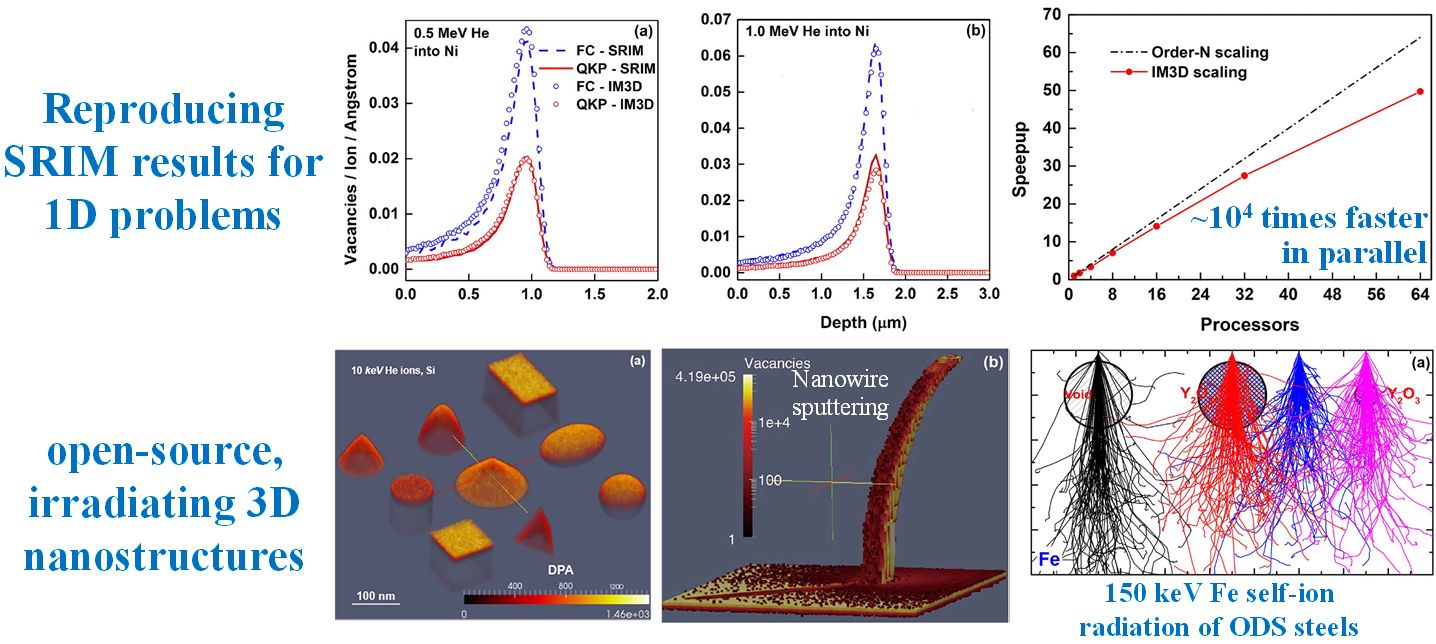

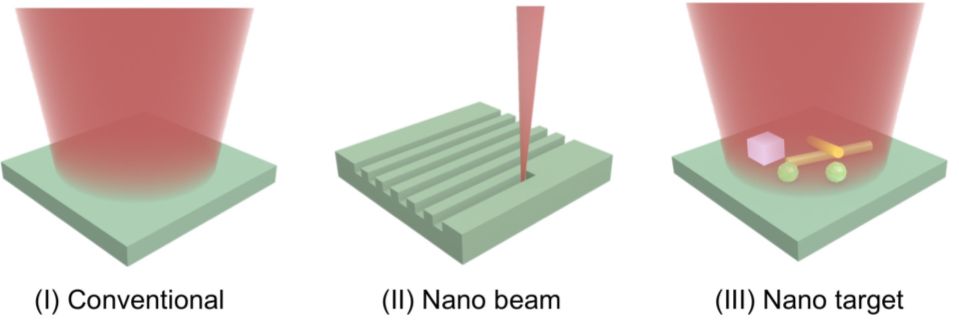

As a result, we have developed IM3D: an open-source, MPI-parallelized and full-3D Monte Carlo simulation code for ion radiation in matter. Using IM3D, we have found that traditional 1D or semi-3D simulation codes such as SRIM could lead to significant errors in the nano-beam and nano-target cases [Nanoscale 10 (2018) 1598-1606]. We also explored the influence of surface roughness on ion implantation and sputtering of materials [Nuclear Fusion 57 (2017) 016038].

Official website of IM3D:

http://li.mit.edu/im3d/

Publications:

[7] Effects of Recoil Spectra and Electronic Energy Dissipation on Defect Survival in 3C-SiC, Lauren Nuckols, Miguel L. Crespillo, Yang Yang, Ju Li, Eva Zarkadoula, Yanwen Zhang and William J. Weber, Materialia, (2021) 101023.

[6] Sample spinning to mitigate polarization artifact and interstitial-vacancy imbalance in ion-beam irradiation, Cui-Lan Ren, Yang Yang, Yong-Gang Li, Ping Huai, Zhi-Yuan Zhu & Ju Li, npj Computational Materials, (2020) 189

[5] Focused-Helium-Ion-Beam Blow Forming of Nanostructures: Radiation Damage and Nanofabrication, Chung-Soo Kim, Richard G Hobbs, Akshay Agarwal, Yang Yang, Vitor R Manfrinato, Michael P Short, Ju Li and Karl K Berggren, Nanotechnology, 31 (2020) 045302.

[4] More Efficient and Accurate Simulations of Primary Radiation Damage in Materials with Nanosized Microstructural Features or Ion Beam, Ju Li, Yang Yang, and Michael P. Short., Handbook of Materials Modeling. Volume 2 Applications: Current and Emerging Materials, (2018).

[3] Nano-beam and nano-target effects in ion radiation, Yang Yang, Yong Gang Li, Michael P. Short, Chung-Soo Kim, Karl K. Berggren and Ju Li, Nanoscale 10 (2018) 1598-1606.

[2] Ion radiation albedo effect: influence of surface roughness on ion implantation and sputtering of materials, Yong Gang Li, Yang Yang, Michael P. Short, Ze Jun Ding, Zhi Zeng and Ju Li, Nuclear Fusion 57 (2017) 016038.

[1] IM3D: A parallel Monte Carlo code for efficient simulations of primary radiation displacements and damage in 3D geometry, Yong Gang Li, Yang Yang, Michael P. Short, Ze Jun Ding, Zhi Zeng and Ju Li, Scientific Reports 5 (2015) 18130.

3. Mat-TRIM: an open-source, and handy Monte Carlo simulation code for ion radiation in nano-structured materials

This MATLAB code, named Mat-TRIM, is the seed of the whole IM3D project. Mat-TRIM is developed by Yang Yang independently as a graduate course term-project at MIT in Spring 2013. Although this program is simple, it captures the key physics in ion radiation with good accuracy. Using it, we have demonstrated the need of full-3D simulation for ion radaition in nanstructured materials.

Through the term-project, Prof. Ju Li saw the value of full-3D Monte Carlo simulations for ion radiation. He then organized a team, including Prof. Michael Short, Dr. Yonggang Li (visiting scholar in Ju’s group at that time, now at CAS of Hefei, China) and me, to develop a MPI-Parrallized, full-3D code for ion radiation. A more advanced code, IM3D, is developed by our team later.

Publication:

[1] Monte Carlo simulation of PKA distribution along nanowires under ion radiation, Yang Yang, Michael P. Short, and Ju Li., Nuclear Engineering and Design, 340 (2018) 300-307.